Precision Die Casting Solutions

Our team at SIM is dedicated to delivering precision in die casting, so you don’t have to worry about the complexities. With expertise, quality craftsmanship, and a commitment to excellence, we handle every detail to ensure die-cast parts that meet the highest standards. Let us focus on the hard work, so you can focus on achieving success.

High Pressure Aluminum Die Casting

We supply high-quality casting parts for the automotive, electronics, agricultural machinery, and household appliance industries, utilizing a standardized production system. Our processes adhere to the IATF Quality Management System, and we offer die-casting capabilities ranging from 350 to 650 tons.

Finishing Process

Finishing is a crucial process that requires precision and expertise. It demands the skill and experience of our well-trained team to ensure every piece is handled with care. Our focus is on removing burrs and unwanted excess material without causing any damage to the workpiece. Each step is thoroughly inspected to guarantee quality before the product moves on to the next stage of production.

Shot Blasting Process

Shot Blasting is a process designed to enhance the surface quality of a workpiece, ensuring a beautiful and consistent finish. We utilize modern, high-standard machinery that operates with exceptional efficiency. In addition to creating a smooth and uniform appearance, Shot Blasting effectively removes small burrs lodged in tight spaces or small holes—areas that standard tools cannot reach.

Heat Treatment Process

Machining Process

High Pressure Die Casting Machine list

1. HD-350 Ton TOSHIBA 1 unit

2. HD-400-01 Ton TOSHIBA 1 unit

3. HD-400-02 Ton TOSHIBA 1 unit

4. HD-650 Ton YOTA 1 unit

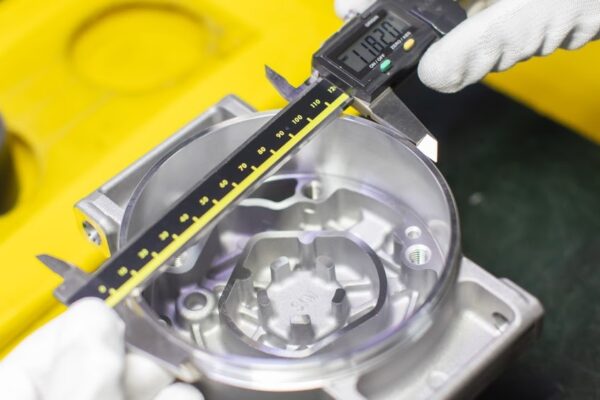

Quality Control

Our quality control processes are meticulously aligned with automotive industry standards, ensuring every product meets the highest benchmarks for safety, precision, and reliability. By adhering to stringent protocols such as IATF 16949:2016 and incorporating advanced inspection technologies, we consistently deliver components that exceed customer expectations and perform flawlessly under demanding conditions.

Quality Equipments

- Weight Scale

- Infrared Thermometer

- Coolant Tester

- Double Column Height Gauge

- Vernier Depth Gauge

- Dial Gauge

- Depth Gauge

- Gauge Block

- V-Anvil Micrometer

- Digital Vernier Caliper

- Coordinate Measuring Machine

- Vacuum Emission Spectrometer

- Thread plug gauge

- Spectrochemical Reference Materials

- Digital Thermometer

- Contour

- Surface Roughness Tester

- Roughness Specimen

- Thread Ring Gauge

- Hardness Tester

Customer References

We are dedicated to delivering precision and quality, ensuring our parts meet the automotive and household sector’s rigorous standards for durability, lightweight design, and cost efficiency.

Industry-Standard Quality for Automotive Parts

We achieved ISO 9001:2008 certification in October 2015 and were certified to

IATF 16949:2016 standards in November 2022, reflecting our commitment to meeting the rigorous demands of the automotive industry. Our quality improvement initiatives are continuing